Tappex Heat Inserter customised to manufacturing process resulting in cost and time savings

A local moulding company, who makes interior components for the automotive industry, recently contacted us having researched our Generation 3 multi-point Heat Installation tool.

A local moulding company, who makes interior components for the automotive industry, recently contacted us having researched our Generation 3 multi-point Heat Installation tool.

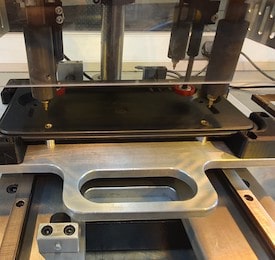

They had an injection moulded component that required post mould insertion of 4 Tappex Multiserts. Our customer told us they are keen to use new and innovative equipment and to develop new methods to constantly improve production and we were able to help them achieve these goals also increasing productivity and saving costs in the manufacturing process of this component.

Our Heat Inserter has the ability to have multiple heat cartridges of different lengths

Our Heat Inserter is also capable of holding heat cartridges of different lengths which is very beneficial to the customer if they have multiple inserts to heat insert into the component at different heights.

A custom-made jig allowing for easy and repeatable positioning of the plastic moulded component