How Tappex helped save the smooth production of 1500 luxury SUVs per week

Discover how Tappex’s Technical Advisory Service can prevent small issues from becoming big multi-million-pound problems…

In the world of automotive engineering design, it’s sometimes the smallest components that can cause the biggest headaches. This exact issue was experienced by a leading global automotive manufacturer when a seemingly insignificant part threatened to jeopardise the quality of 1500 luxury SUVs every week – the equivalent of £150m in weekly sales.

In the world of automotive engineering design, it’s sometimes the smallest components that can cause the biggest headaches. This exact issue was experienced by a leading global automotive manufacturer when a seemingly insignificant part threatened to jeopardise the quality of 1500 luxury SUVs every week – the equivalent of £150m in weekly sales.

And the culprit? A tiny threaded insert in the armrest of the vehicles. The problem? Insert pull-out failures, in one position in particular, was leading to production delays, reworking and negative customer feedback.

Enter Tappex, with over 60 years of experience in solving fastening challenges. We didn’t just offer a quick fix, our technical team engineered a bespoke solution.

Working closely with the automotive OEM and a Tier 1 supplier, Tappex designed a new heat-installed insert, advised on correct hole geometry and insert positioning, and optimised the installation process. From the point of enquiry, testing and identifying the failure mode was completed swiftly by our Engineering Team. The design of the new insert was agreed, samples were produced and tested in application, and after sign off, production volume commenced at Tappex. As a manufacturer of threaded inserts, Tappex are able to react quickly to our customers’ needs.

The result?

The result?

A solution that not only met but exceeded the required 1000N pull-out performance standard. We started supplying 50,000 of the new inserts needed every week (14 parts across two seats per vehicle) to allow smooth production of the 1500 vehicles to continue, improving quality and reducing failures on this particular element. Through further development, we were also able to reduce the insert use to six per assembly, rather than seven, resulting in further efficiency savings.

Don’t just fix problems – prevent them

It’s not just about fixing problems though – we absolutely will of course, but what we really want to do is help you prevent them. By involving Tappex at the start of your design process, you can avoid costly delays and redesigns, ensure optimal performance of your components and take advantage of our expertise in threaded inserts for plastics, woods, light metal alloys, and composite materials. Don’t wait for a tiny component to become a big problem. Contact Tappex today and drive your designs to success from day one.

A legacy of excellence

Tappex has been at the forefront of threaded insert technology since 1956. Headquartered in Stratford upon Avon, UK,we also have privately-owned subsidiaries in Sweden and Finland, and a well-established global network of independent technical distribution partners and sales agents.

We are specialists in the manufacture of threaded inserts for plastics, light metal alloys, and composite materials, and are globally-renowned for the calibre of our cost-effective fastening solutions.

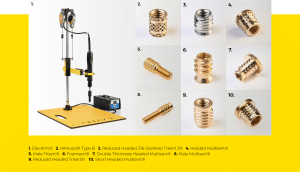

We offer a broad range of brass, steel, stainless steel and Titanium inserts, ranging from M1.4 to M30, as well as customised solutions for specific mechanical requirements.

The thread that fastens it all together

While we typically stock around 60 million standard inserts for quick off-the-shelf delivery, and can facilitate production runs of a few thousand pieces to millions, it’s our problem-solving technical service that really sets us apart. We offer early design collaboration, working with you from project inception, to ensure optimal fastening solutions from day one.

If you do have an existing part fail though, we’ll bring our trouble-shooting expertise to identify the root cause and engineer top notch solutions. Our processes use rigorous testing, high-tolerance parameters and quality materials to keep your production lines running.

Whether you’re designing a new component or trouble-shooting an existing one, our technical experts are here to help drive your designs to success from day one.

Whether you’re designing a new component or trouble-shooting an existing one, our technical experts are here to help drive your designs to success from day one.

With Tappex on your team, your small parts won’t become massive problems – they’ll be the building blocks of your next great design.